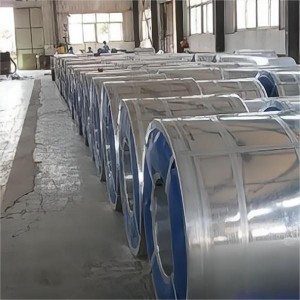

Alloy High Pressure Seamless Steel ASTM A213 Grade T11 T12 Tubing

Seamless Steel Tube ke phala e telele ea tšepe e nang le karolo e se nang letho 'me ha e na meroko ho e potoloha.Peipi ea tšepe e na le karolo e ka holimo e sekoti 'me e sebelisoa ka bongata e le phaephe ea ho tsamaisa maro a kang oli, khase ea tlhaho, khase, metsi le lisebelisoa tse itseng tse tiileng.Ha ho bapisoa le tšepe e tiileng joalo ka tšepe e chitja, phala ea tšepe e se nang seamless e bobebe ka boima ba eona ha e e-na le matla a tšoanang a ho kobeha le a torsional, 'me ke mofuta oa tšepe e nang le likarolo tse fapaneng tsa moruo, e sebelisoang haholo ha ho etsoa likarolo tsa meralo le tsa mochini. e le lipalangoang tsa oli, litšepe tsa litepisi, liforeimi tsa libaesekele, le litšepe tse sebelisoang ha ho hahoa.Alloy seamless tšepe pipe e etsa likarolo tse bōpehileng joaloka selikalikoe, e ka ntlafatsa tšebeliso ea thepa, ea nolofatsa mokhoa oa ho etsa lihlahisoa, lisebelisoa tsa ho boloka le lihora tsa ho sebetsa, tse kang li-ring ring, li-jack sets, joalo-joalo, li 'nile tsa sebelisoa haholo ho etsa phala ea tšepe.Alloy seamless tšepe pipe kapa mefuta e fapaneng ea libetsa tse tloaelehileng tsa bohlokoa, libarele tsa lithunya, libarele, joalo-joalo ho phala ea tšepe ho etsoa.Ho phaella moo, karolo e chitja ka har'a khatello ea mahlaseli a ka hare kapa a ka ntle, matla a tšoana haholo, ka hona, boholo ba phala ea tšepe e se nang seamless ke tube e chitja.

1.Liphaephe tsa tšepe tse se nang metsi bakeng sa li-cylinders tsa khase: haholo-holo tse sebelisetsoang ho etsa likhase tse sa tšoaneng tsa khase le li-hydraulic cylinders.Lisebelisoa tsa eona tsa moemeli ke 37Mn, 34Mn2V, 35CrMo, joalo-joalo.

2.Lipeipi tsa tšepe tse se nang seamless tse chesang tse chesang bakeng sa litšiea tsa hydraulic: haholo-holo tse sebelisetsoang ho etsa litšehetso tsa hydraulic le li-cylinders le litšiea bakeng sa merafo ea mashala, hammoho le li-cylinders tse ling tsa hydraulic le litšiea.Lisebelisoa tsa eona tsa moemeli ke 20, 45, 27SiMn, joalo-joalo.

3.High khatello e seamless tšepe pipe bakeng sa enjene disele: haholo-holo sebelisoa bakeng sa tsamaiso disele ente tsamaiso e phahameng khatello ea oli pipe.Peipi ea eona ea tšepe hangata e huloa ka serame, 'me thepa ea eona e emelang ke 20A.

4.Pape ea tšepe e sa tsitsang e batang kapa e batang: haholo-holo e sebelisetsoang mehaho ea mechine, thepa ea khatello ea carbon, e hlokang ho nepahala ha boemo bo phahameng, phala e ntle ea holim'a metsi.thepa ea eona ea moemeli 20, 45 tšepe, joalo-joalo.

1.Hobaneng o re khetha?

Khamphani ea rona e bile Alibaba.com ka lilemo tse 12.Re laola boleng ba lihlahisoa ka thata haholo, ho na le batho ba khethehileng bakeng sa boleng.

Haeba u fumane theko e tlase ho tsoa ho morekisi e mong, re tla lefa bareki habeli ka theko e holimo.

2.Na nako ea hau ea ho fana ka nako e kae?

Ho ya ka bongata.Ka kakaretso ka hare ho matsatsi a 2-7 haeba setokong.Le matsatsi a 15-20 haeba a se teng.

3.Lipehelo tsa hau tsa tefo ke life?

A: Ka T/T 30% esale pele, le 70% pele ho pepa.

B:100% L/C ha u bona.

C:Ka T/T 30% esale pele, le 70% L/C ha u bona.

4.Na u fana ka mehlala?Na ke mahala?

E, re fana ka sampuli mahala empa ha re lefelle litšenyehelo tsa thepa.

5.Ho thoe'ng haeba moreki a sa khotsofala?

Haeba ho na le bothata ka sehlahisoa, re nka boikarabelo bo feletseng.

Haeba ho na le bothata tšebetsong ea lipalangoang, re tla u thusa ho bo rarolla.