Astm A106b Peipi ea tšepe e se nang seam e phahameng e batang haholo

Pipe ea tšepe e nepahetseng ka mokhoa o phahameng o batang ke mofuta o mocha oa phala ea tšepe, eo tšobotsi ea eona e ka sehloohong e leng ho nepahala ho phahameng.Hangata tse peli-rolara leloala le tse tharo-rolara leloala tlhahiso ea tshebetso tse peli tsa tlhahiso, tse tharo-rolara leloala tlhahiso ea batang phuthoa seamless tšepe tube ho nepahala e phahameng, e ka laoloa ka hare ho silika tse seng kae, empa theko e batlang e le phahameng.Khothaletso ea phahameng. -Li-tubes tsa tšepe tse nepahetseng tse huleloang ka mokhoa o nepahetseng tse batang ho boloka tšepe, ho ntlafatsa ts'ebetso ea ts'ebetso, ho boloka matla Ho thoeng ka mokhoa o nepahetseng o phahameng o batang oa seamless tšepe o bua ka ho nepahala ha dimensional ka hare le ka ntle (lebaka la mamello) le thata, ka hare le ka ntle. Qetella, ho pota-pota, ho otloloha, ho ka boloka lihora tsa machining haholo, ho ntlafatsa tšebeliso ea thepa, ha ho ntse ho thusa ho ntlafatsa boleng ba sehlahisoa.

Mekhoa e meholo ea ho sebetsa e batang ea phala ea tšepe ke ho hula ka mokhoa o batang le mokhoa o batang oa ho roala.Lilemong tsa morao tjena, le ntshetsopele ya saense le thekenoloji, le ntshetsopele ya mokhoa batang ho ohla, ka mokhoa ona ho ka hlahisa bophara e khōlō, phahameng-ho nepahala batang-rollwa li-tubes le batang-phuthoa le mefuta e fapaneng sefapano karolo.Cold tshebetso ya tšepe phala thepa e tala e ka chesang-rollwa seamless tšepe phala e ka boela welded phala.Ntho e tloaelehileng ea mokhoa oa ho sebetsa o batang oa pipe ea tšepe ke ho nepahala ho phahameng, ho hlaba holimo, ho ka hlahisa li-tubes tse tšesaane haholo (ho fihla ho 0.05 ~ 0.01mm) le tse ntle haholo (bophara ho fihlela ho 0.3 ~ 0.1 mm) capillary. liphaephe.Liphaephe tse se nang seamless ke liphaephe tse nang le liphaephe tse sekoti, tse sebelisoang ka bongata e le liphaephe tsa ho tsamaisa maro, joalo ka liphaephe tsa ho tsamaisa oli, khase ea tlhaho, khase, metsi le lisebelisoa tse itseng tse tiileng.Ha ho bapisoa le litšepe tse tiileng tse kang tšepe e chitja, phala ea tšepe e bobebe ka boima ba 'mele ha ho kobeha le matla a torsional a tšoana,' me ke tšepe e fapaneng ea moruo, e sebelisoang haholo boenjiniere ba liphaephe.

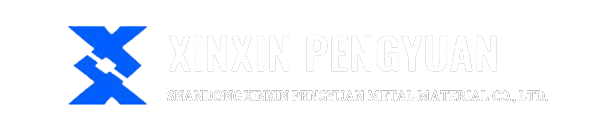

Tlhahiso : Ts'ebetso Round tube e se na letho → futhumatsang → ho phunya → rolara tse tharo skew rolling, rolling e tsoelang pele kapa extrusion → ho tlosoa ha tube → boholo (kapa ho fokotsa) → ho pholisa → ho otlolla → tlhahlobo ea hydrostatic (kapa ho lemoha liphoso) → ho tšoaea e entsoeng ka li-ingots tsa tšepe kapa likheo tsa li-tube tse tiileng ka ho phunyeha ho etsa li-tubes tsa capillary, ebe li chesa, tse batang kapa tse huloang ka serame.

1.Pipe ea seamless ea sebopeho

(Lipeipi tsa tšepe tse se nang seam bakeng sa ho etsa liphaephe, likepe, lisebelisoa, lisebelisoa le meaho ea mochini)

2.Seamless pipe bakeng sa phetiso ea mokelikeli

(Lipeipi tse sebelisetsoang ho tsamaisa maro ke lipeipi tsa ho tsamaisa oli, khase ea tlhaho, khase, metsi le lintho tse itseng tse tiileng.)

3.Seamless tube bakeng sa boiler.

4. Phaephe e tsamaisang thepa: E sebelisoa haholo bakeng sa ho tsamaisa metsi, oli le khase.

5. Pipe ea mohala: E sebelisoa haholo-holo bakeng sa tšireletso ea mohala

Likarolo tsa 6.Auto, liphaephe tsa tšepe tsa hydraulic

1. Ke hobane'ng ha u re khetha?

Khamphani ea rona e bile lilemo tse 12.Re laola boleng ba lihlahisoa ka thata haholo, ho na le batho ba khethehileng bakeng sa boleng.

Haeba u fumane theko e tlase ho tsoa ho morekisi e mong, re tla lefa bareki habeli ka theko e holimo.

2. Nako ea hau ea ho fana ka nako e kae?

Ho ya ka bongata.Ka kakaretso ka hare ho matsatsi a 2-7 haeba setokong.Le matsatsi a 15-20 haeba a se teng.

3. Lipehelo tsa hau tsa tefo ke life?

A: Ka T/T 30% esale pele, le 70% pele ho pepa.

B:100% L/C ha u bona.

C:Ka T/T 30% esale pele, le 70% L/C ha u bona.

4. O fana ka mehlala?Na ke mahala?

E, re fana ka sampuli mahala empa ha re lefelle litšenyehelo tsa thepa.

5. Ho thoe'ng haeba moreki a sa khotsofala?

Haeba ho na le bothata ka sehlahisoa, re nka boikarabelo bo feletseng.